Hydrogen Fluoride Ion Cleaning (HFIC)

HFIC is used to clean turbine components at a molecular level, ensuring oxide-free surfaces for subsequent brazing, welding, or coating.

It's a non-destructive and precise method for critical repair zones.

Vacuum Brazing

Used to join high-value parts like honeycomb seals, shrouds, or cooling elements, vacuum brazing creates strong, clean joints without oxidation.

We have extensive experience in performing vacuum brazing for gas turbine engine components and have developed a wide range of custom brazing alloy compositions tailored for various repair tasks.

Electron Beam Welding

EB welding is indispensable for deep, narrow welds with minimal thermal distortion, making it ideal for thin-walled or precision components.

Thanks to the 5х coordinate EB gun movement, it is possible to weld complex curved seams in automatic mode simultaneously with scanning the quality of the weld seam.

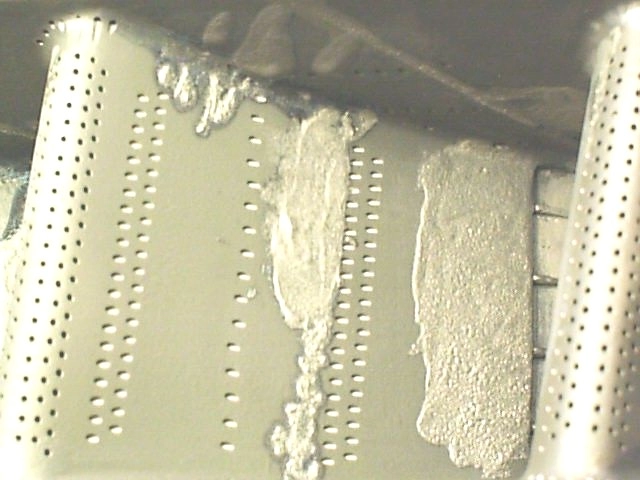

TIG Welding

TIG welding is used for precision manual repairs of combustor panels, nozzle guide vanes, blade’s tip and structural engine elements. It provides high-quality, ductile welds with excellent control.

Our TIG welding processes also incorporate preheating and accompanied techniques for the welding build up of material on blades and vanes, ensuring metallurgical compatibility and minimizing stress.

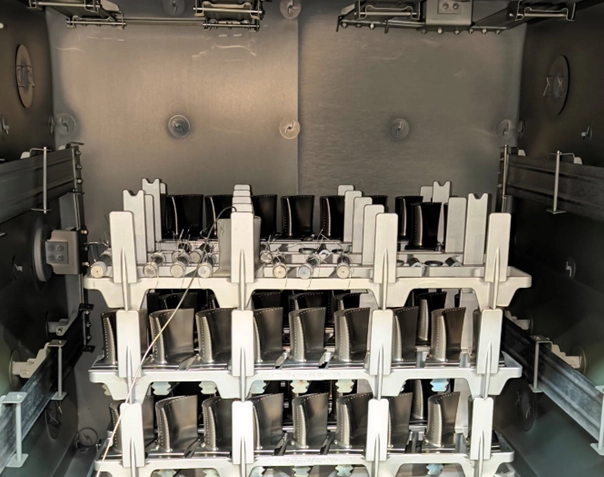

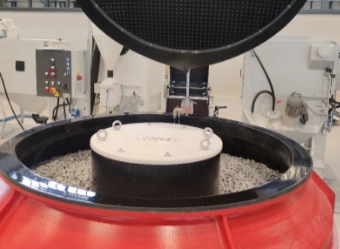

Vacuum Heat Treatment

Vacuum heat treatment capabilities enable multi-stage repair cycles with tailored temperature control for different superalloys and service conditions.

Critical for restoring or enhancing the microstructure of high-performance alloys, this treatment is also used post-weld or post-braze to relieve stress and homogenize structure.

Our vacuum heat treatment equipment supports temperatures up to 1350°C, with working dimensions up to 600×600×900 mm, and argon cooling pressure up to 6 bar — ideal for treating complex GTE components.

Air Heat Treatment

Air heat treatment supports processes like solution annealing or aging in steels and nickel-based alloys, used after mechanical processing or repairs to restore material properties.

The operation is also used to control the quality of removal of various types of coating on turbine parts after their operation.

Chemical Stripping

We offer both alkaline stripping ideal for removing ceramic TBCs—and acidic stripping for removing aluminide, platinum-aluminide, and MeCrAlY coatings from new and after operation parts.

Our processes ensure efficient removal without compromising the substrate.

Waterjet Robotic Stripping

Robotic high-pressure waterjet system operates at pressures up to 4000 bar, allowing for precise and safe removal of ceramic (APS, EBPVD) and other seal coatings from GTE parts without damaging the base material.

Robotic & Manual Grit Blasting

Ensures surface activation before coating or coating stripping. Robotic blasting ensures repeatability on serial parts, while manual blasting supports custom repair tasks.

Shot Peening

This mechanical surface treatment induces beneficial compressive stresses that significantly improve fatigue strength and durability.

It is used not only for life extension of rotating components such as turbine disks and blades, but also for densifying the structure of metallic coatings and strengthening blade roots (e.g., fir-tree or dovetail sections) to enhance resistance to mechanical loading during operation.

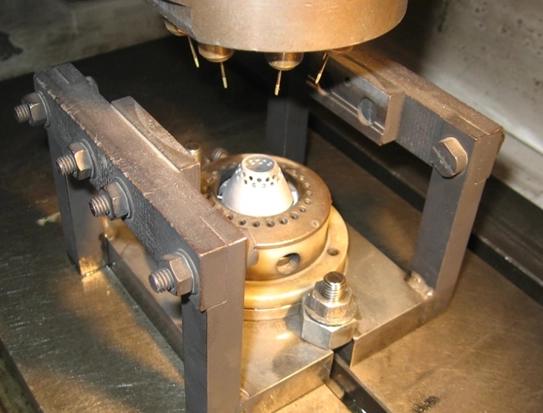

EDM Drilling

Used for restoring or modifying cooling holes in turbine blades and vanes. Enables micron-level accuracy in hard-to-machine superalloys.

Vibropolishing

Improves surface finish, removes burrs, and reduces stress concentrations in hot-section GTE components before coating or inspection.

Ultrasonic Cleaning

Removes fine contaminants from cooling passages or internal cavities of turbine components, crucial before non-destructive testing or coating.

Grinding & Polishing

Used to restore final dimensions and surface quality after build-up repairs or coating processes.

Manual polishing is also essential for new blades prior to coating application, ensuring the required surface roughness for optimal adhesion of thermal barrier coatings.

Machining

Our precision machining supports reworking or requalification of parts such as bearing housings, flanges, and air seals.

Machining is also used after repair operations to restore final geometry and prepare surfaces for coating application.