Metallographic Analysis

Supports failure analysis, quality verification, and coating structure evaluation. Used to thickness measurement, evaluation of coating distribution across the part surface, examine grain size, phase distribution, and porosity in coatings and base materials and compliance with specification requirements.

Our laboratory has all the necessary equipment for preparing samples, which are analyzed using optical and scanning (SEM) microscopes.

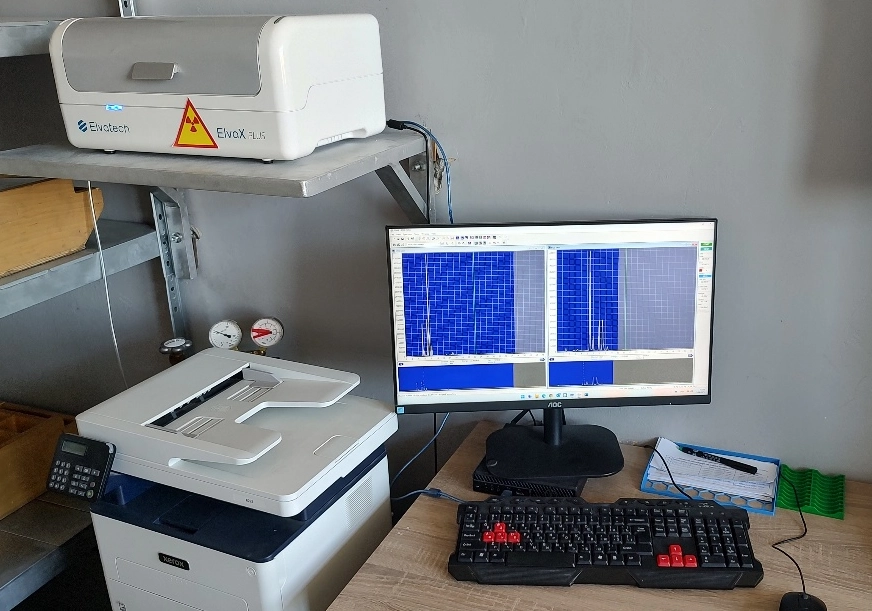

X-Ray Fluorescence (XRF) Spectrometry

Used to verify alloy composition and coating element content.

Essential for ensuring material and coating composition compliance with aerospace standards during both coating and repair.

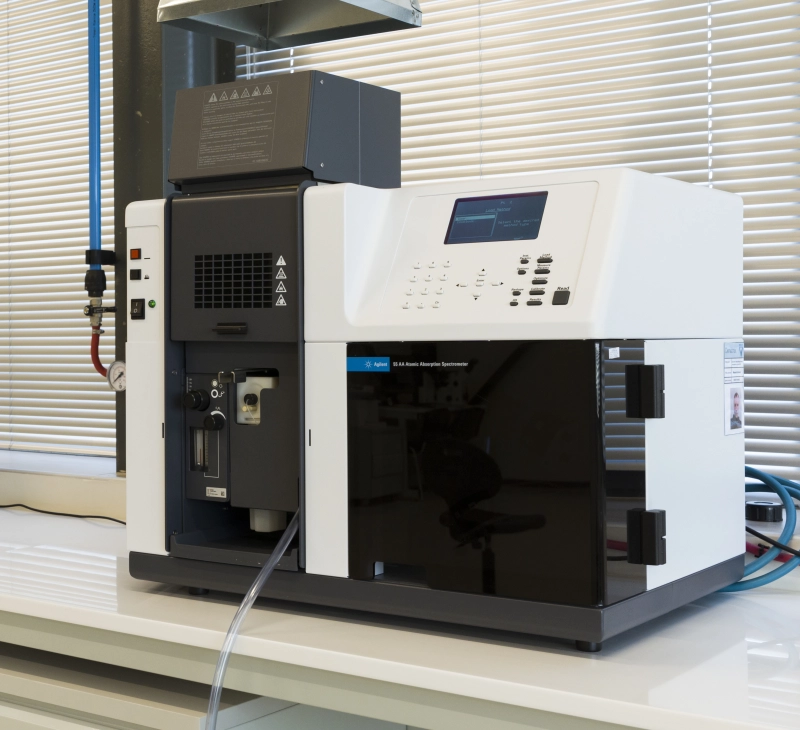

Atomic Absorption Spectrophotometry (AAS)

Allows detection of trace elements and contaminants in alloys and coatings—critical for high-performance turbine materials where purity is key.

In addition, AAS is used to monitor platinum concentration in plating baths, ensuring optimal deposition conditions and high-quality coating performance for demanding customer requirements.

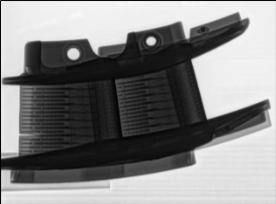

X-Ray CT Tomograph

Provides non-destructive 3D visualization of internal defects, porosity, or geometric deviations in parts, cooling passages, or bonded joints.

Our automated CT system is capable of inspecting even large components and verifying assembly quality of complex internals in vanes, such as baffles, cooling inserts etc.

Surface Roughness Measurement

Used to verify surface finish after coating removal or prior to coating application, ensuring proper adhesion and aerodynamic performance.

Eddy Current Thickness Evaluation

Non-destructive technique to measure coating thickness on complex shapes—important for QA after coating restoration.

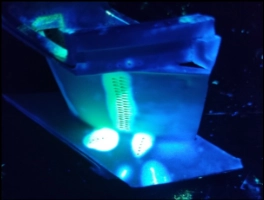

Fluorescent Penetrant Inspection (FPI)

Essential for detecting cracks and surface-breaking flaws in turbine components before and after repair or machining, helping to ensure structural integrity before re-entry into service.

Our semi-automated FPI line supports multiple types of penetrants and developers, enabling us to perform inspections at Level 4 sensitivity—the highest level per ASTM E1417 and ISO 3452 standards. This ensures the detection of the smallest surface flaws in critical aerospace components.