Coating & Repair

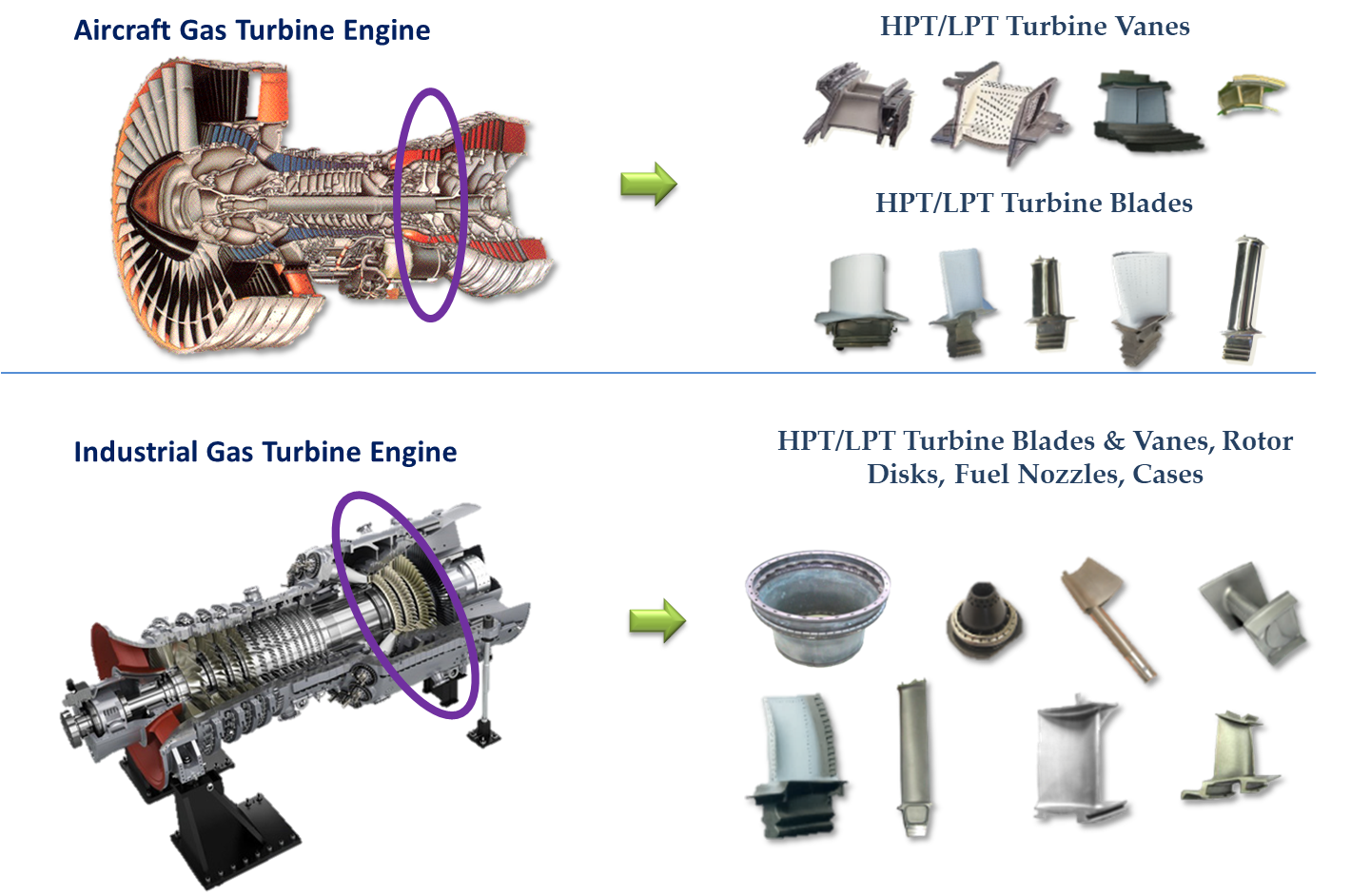

Since 1994, Sigmatech’s subsidiary, Paton Turbine Technologies, has specialized in the application of advanced ceramic and metal coatings to aircraft engine components using Electron Beam Physical Vapor Deposition (EBPVD) technology. Over the years, our expertise has grown to include parts for major engine models such as the JT9D, PW4000, PW4090, V2500, CF6, CFM56, and others, as well as parts for industrial gas turbines.

We offer a diverse range of coating technologies, including:

• Electron Beam Physical Vapor Deposition (EBPVD) – metal and ceramic

• Atmospheric Plasma Spraying (APS)

• High-Velocity Oxygen Fuel (HVOF) Spraying

• Vapor Phase Aluminizing and Chromizing (VPA)

• Platinum Plating (PP)

Our turbine part repair capabilities began in 2002 and have since expanded to include full-cycle services. These encompass the removal of unconditional coatings (chemical and mechanical), cleaning, defect identification and repair routing, and core processes such as fluoride ion cleaning, welding, brazing, and heat treatment. Once structural repairs are completed, appropriate coating systems are reapplied.

Depending on complexity, a repair process may involve up to 60 distinct technological steps. To ensure exceptional quality and product reliability, non-destructive testing (NDT) is conducted after nearly every stage. In addition, we routinely perform metallographic analysis on control samples to validate coating performance.

At Sigmatech, we are committed to continuous improvement. By integrating advanced technologies and refining our processes, we deliver high-efficiency, high-quality solutions tailored to the evolving needs of our clients.