EBPVD Ceramic Coating

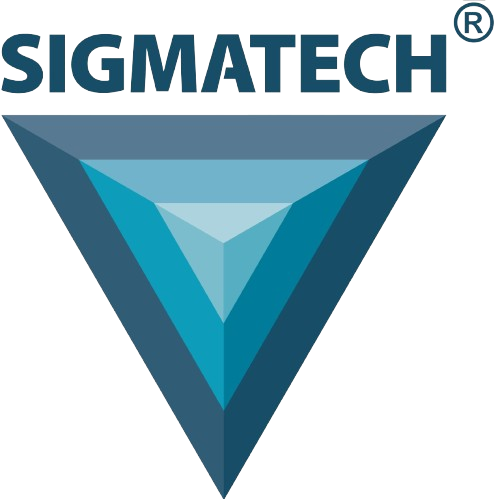

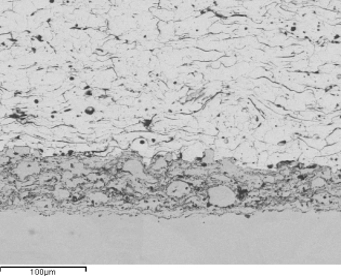

Our Electron Beam Physical Vapor Deposition (EBPVD) technology allows us to apply advanced ceramic thermal barrier coatings (TBCs), primarily based on yttria-stabilized zirconia (ZrO₂+6-8%Y₂O₃), to protect the hot-section parts of gas turbine engines (GTEs).

These coatings form a columnar crystalline structure that accommodates thermal expansion, increasing resistance to thermal cycling and extending the life of turbine blades and vanes.

We also offer next-generation ceramics using rare-earth oxides (e.g., Gd₂Zr₂O₇, Yb₂Zr₂O₇) to reduce thermal conductivity, thereby improving fuel efficiency and reliability in advanced engine designs.

EBPVD Metal Coating

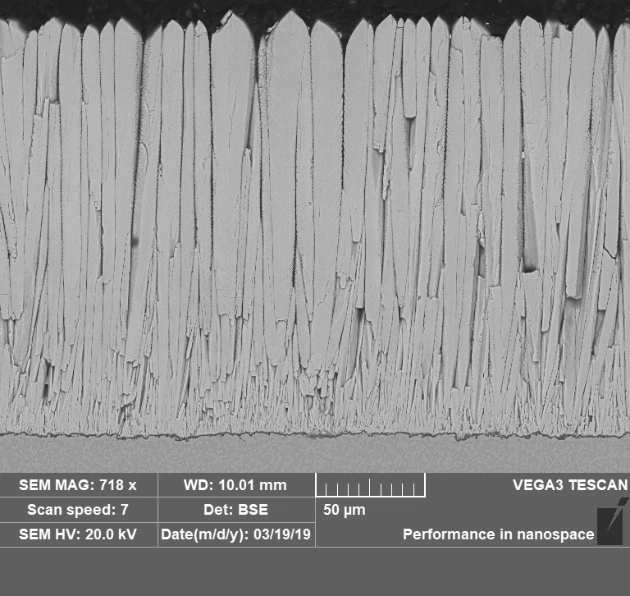

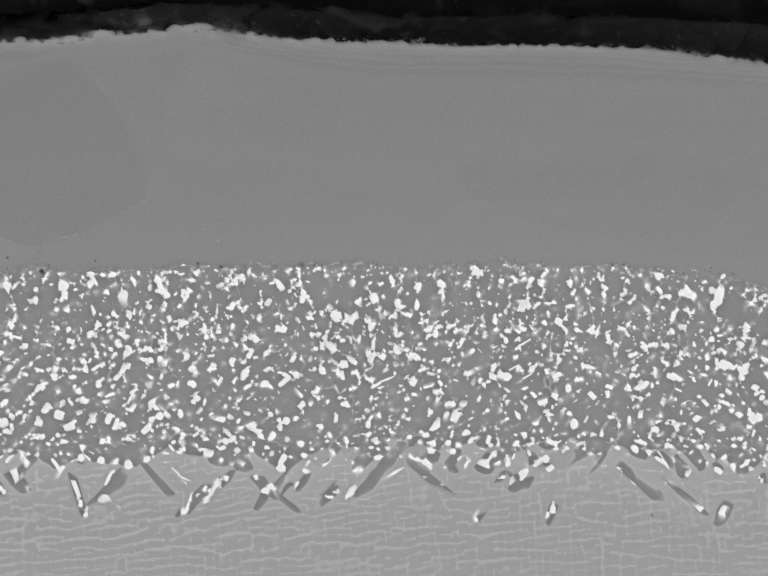

We apply high-quality MeCrAlY (Ni- or Co-based) metallic coatings via EBPVD for both stand-alone protection and as bond coats under ceramic layers.

These coatings provide oxidation and hot corrosion resistance for turbine blades, nozzles, and combustor parts. The process delivers dense, defect-free layers with equiaxed g+β phase structure, rich in β-NiAl, which ensures excellent adhesion, thermal fatigue resistance, and chemical stability in harsh GTE environments.

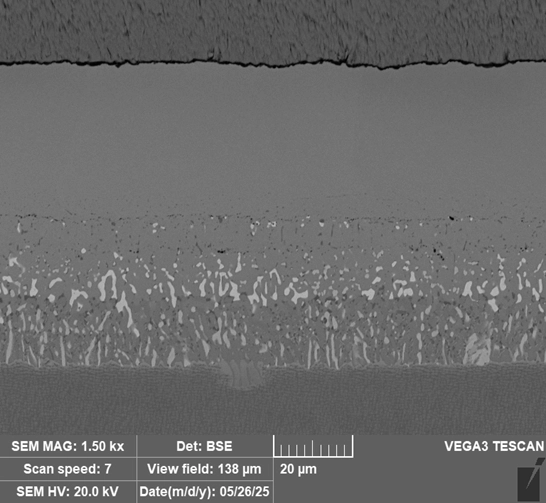

HVOF Coating

High Velocity Oxy-Fuel spraying is used to deposit dense, hard metallic and cermet coatings, such as WC-Co and Cr₃C₂-NiCr, on components subject to erosion, wear, or corrosion.

We also apply MeCrAlY (Ni- or Co-based) coatings via HVOF to provide high-temperature oxidation and corrosion protection, particularly for compressor and combustion section components. Our HVOF workshop features a variety of spray guns, including the time-tested industry standard JP5000, and the advanced eGun system.

The eGun not only offers enhanced spray control and efficiency but also operates with improved environmental performance, aligning with modern sustainability standards.

APS Coating

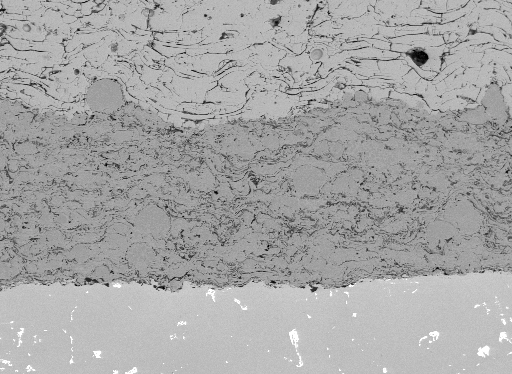

Atmospheric Plasma Spray (APS) technology enables the deposition of a wide range of materials including MeCrAlY metallic layers and ceramic thermal barrier coatings (TBCs) based on yttria-stabilized zirconia or other advance systems.

APS is commonly used on hot-section GTE components to provide both bond coats and outer ceramic layers, especially in refurbishment programs. Our capabilities ensure durable oxidation, corrosion, and thermal protection on geometrically complex components.

VPA (Vapor Phase Aluminizing)

VPA creates diffusion aluminide coatings that reinforce high-temperature oxidation and hot corrosion resistance of nickel- and cobalt-based alloys used in turbine engines.

It is a key process for hot-section parts like turbine blades, vanes, and combustion liners during both manufacturing and overhaul stages.

Platinum Aluminide Coating

We offer high-purity platinum electroplating to serve as a diffusion barrier and oxidation-resistant interlayer in advanced coating systems.

Pt-plating is a vital precursor for forming PtAl coatings, which are widely used on high-stress rotating parts in aero-engines and industrial gas turbine.