SIGMATECH LTD

SIGMATECH LTD, together with its subsidiary LLC Paton Turbine Technologies, with significant experience, an excellent team of specialists, state-of-the-art technologies and modern high-tech equipment, focus their attention on working with the most critical parts of aircraft and industrial gas turbine engines. Our main specialization is the application of hot-resistant and thermal barrier coatings and rejuvenation of the turbine’s hot section parts.

The company is intensively augmenting its scientific and technical potential partly thanks to the close cooperation with LLC Paton Turbine Technologies (Ukraine) where Sigmatech Ltd has a 51% stake.

LLC Paton Turbine Technologies (former Pratt & Whitney-Paton until 2014) was founded in 1993 as a joint venture between Pratt & Whitney (United Technologies Corporation, USA) and E. O. Paton Electric Welding Institute of National Academy of Sciences of Ukraine. Over the years, the company has proved itself as a reliable partner that successfully operates using and implementing the best class practices focused on customer needs and satisfaction.

To date, Sigmatech Ltd has put into operation two production facilities in Bulgaria to perform the following tasks:

- Applying protective coatings using various methods (EBPVD, VPA, HVOF, APS, Pt-Plating).

- Repairing gas turbine parts (Electron Beam / TIG welding, HFIC, Vacuum brazing, EDM drilling, Vacuum / Air Heat Treatment, Shot Peening, Stripping, etc.).

- Manufacturing laboratory and industrial electron beam units designed for EBPVD coating.

The company has its own metallographic laboratory equipped with the newest equipment, which allows for prompt inspection of the quality of the work performed.

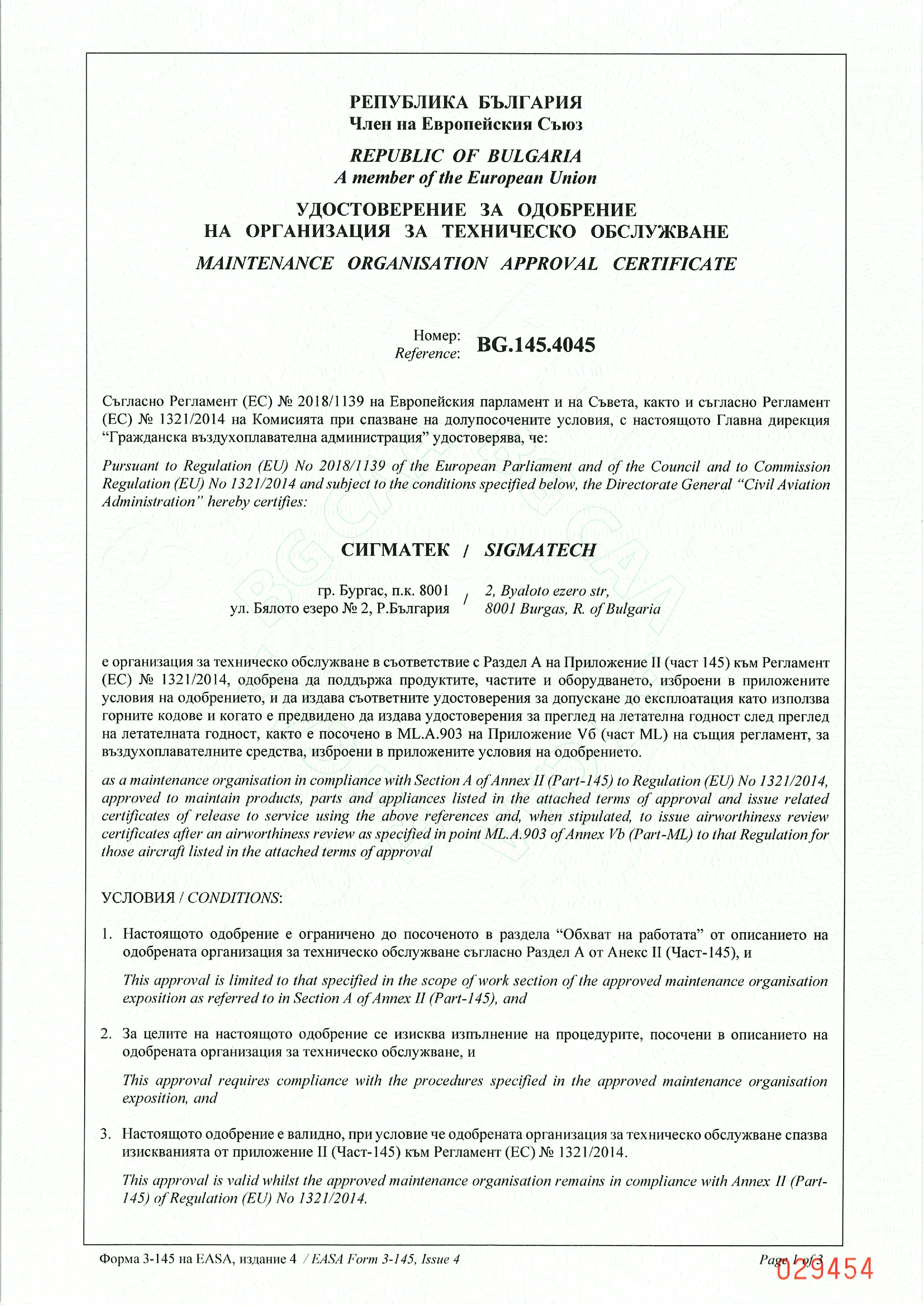

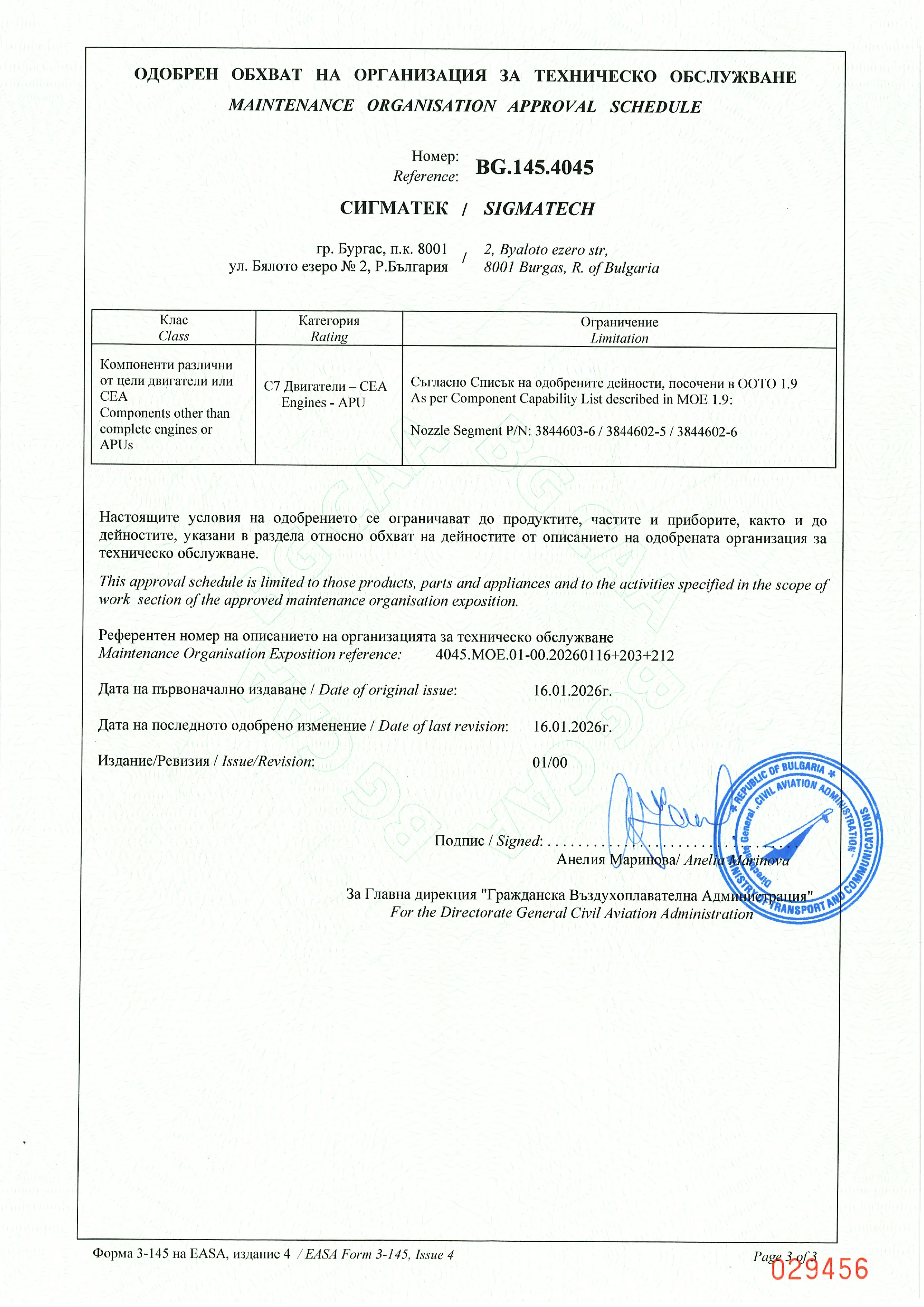

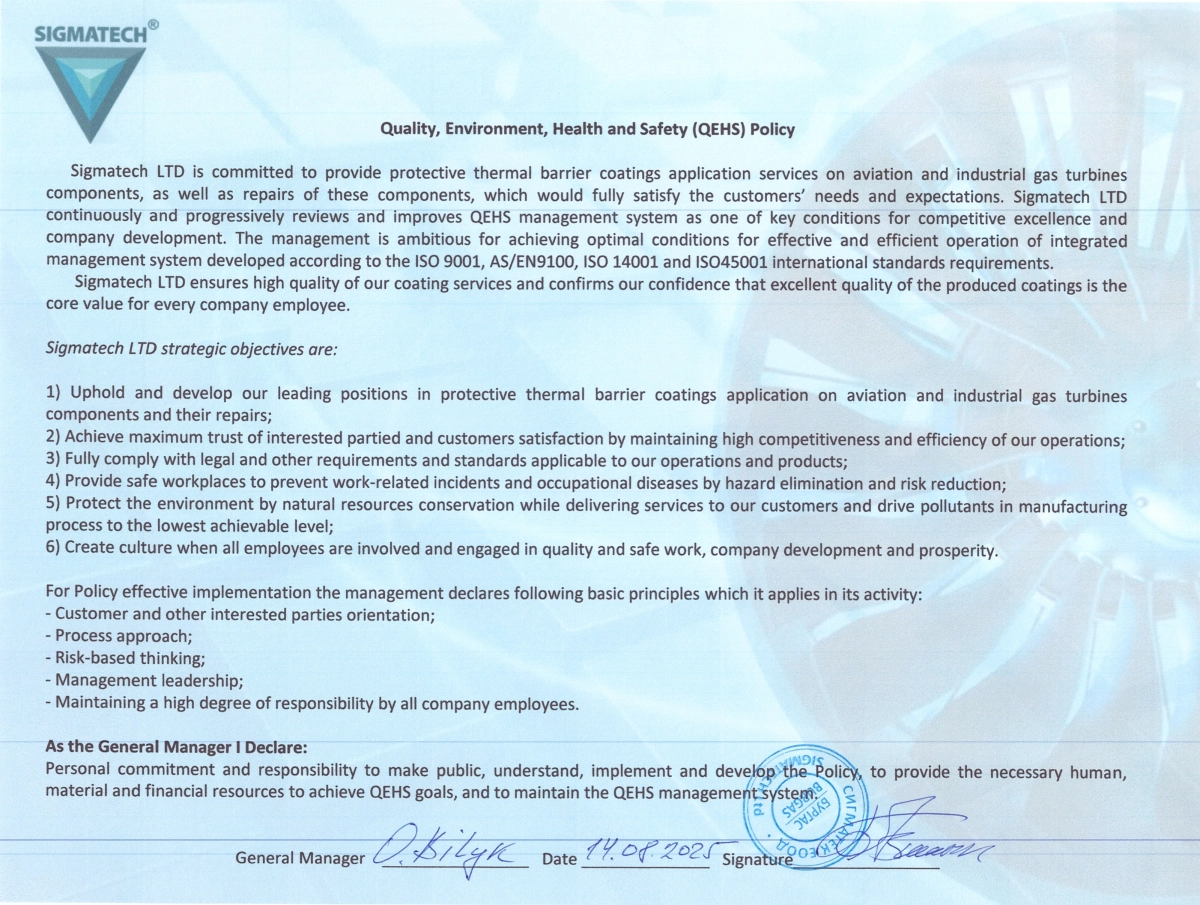

In April 2020, the company successfully passed ISO 9001, ISO 14001 and ISO 45001 audits. In January 16, 2026, Sigmatech obtained the EASA Part-145 Maintenance Organization Certificate, Approval Reference: BG.145.4045, Rating: C7 – Engines / APU.

This milestone reflects our strong commitment to the highest standards of aviation safety, quality, and regulatory compliance.

The certification confirms our capability to perform approved maintenance activities strictly within our authorized scope, in full alignment with EASA Part-145 requirements. In the short term, we are making every effort to obtain FAA certification. In order to attract more customers from among the OEMs, the company is also working to obtain the EN9100 aerospace certificate and the NADCAP certificate.

At the moment, the company's customers are both giants of their industries and small companies. We are constantly developing and having the highly qualified personnel, state-of-the-art technologies, manufacturing capabilities, solid and motivated teams. We can make the best offer to our customers in the industry and ensure efficient positioning in the market of gas turbine engine manufacturing and repair.