SIGMATECH LTD, together with its subsidiary LLC Paton Turbine Technologies, with significant experience, an excellent team of specialists, state-of-the-art technologies and modern high-tech equipment, focus their attention on working with the most critical parts of aircraft and industrial gas turbine engines.

Our main specialization is the application of hot-resistant and thermal barrier coatings and rejuvenation of the turbine’s hot section parts.

EBPVD Coaters

Since 1993, Sigmatech has specialized in the design and manufacture of equipment for electron beam physical vapor deposition (EBPVD) of ceramic and metal coatings.

Coating & Repair

Since 1994, Sigmatech’s subsidiary, Paton Turbine Technologies, has specialized in the application of advanced ceramic and metal coatings to aircraft engine components using Electron Beam Physical Vapor Deposition (EBPVD) technology.

Research & Development

At the core of our innovation lies a dedicated team of engineers and PhD-level specialists with extensive experience in the repair and coating of aircraft and industrial turbine components.

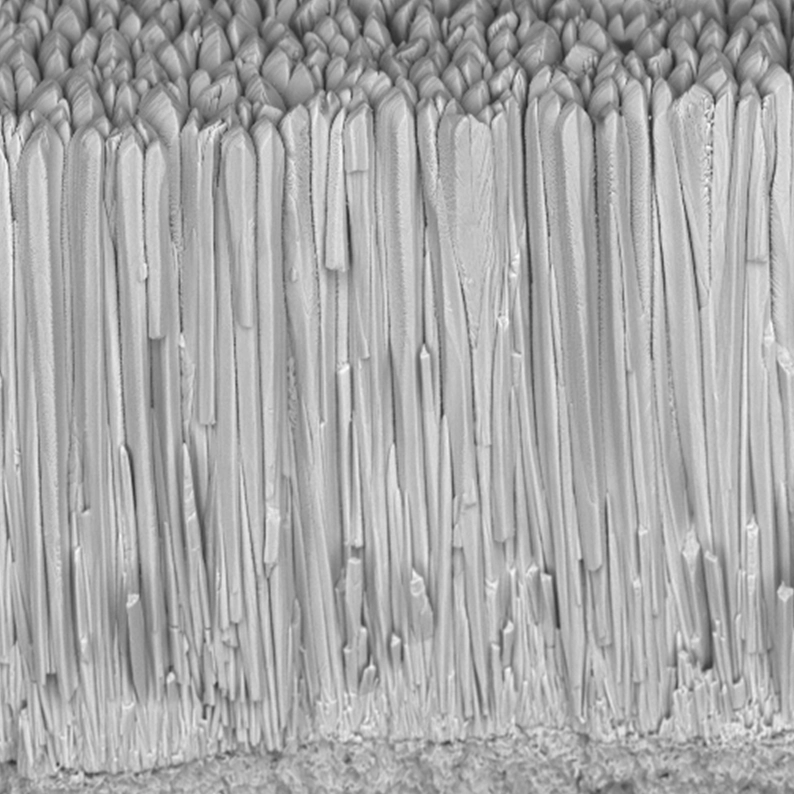

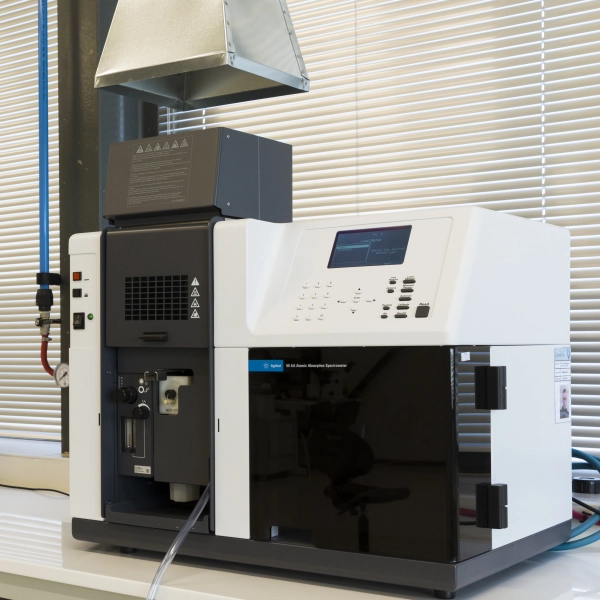

Metallographic Laboratory

When working with critical parts, we must ensure that every process meets the highest quality standards. Our laboratory is equipped with all necessary tools for sample preparation and high-resolution microscopy.

Specific Processes

Operating in the global market inevitably brings challenges related to specialized processes that may be unavailable within a company — often due to high equipment maintenance costs or limited access to advanced technologies.

Markets We Serve

At Sigmatech Ltd., we specialize in the repair and coating of critical components used in aircraft and industrial gas turbine engines.

Aviation

In the aviation sector, safety and reliability are non-negotiable — especially when it comes to hot section engine components.

Power Generation

Modern turbines operate under extreme thermal and mechanical stress, and even minor degradation can affect output.

Oil & Gas

Gas turbines used in oil & gas operations, especially aeroderivative engines, face some of the most demanding environments in the industry.

Why choose Sigmatech?

• Over 30 years of industry experience• High-performance results with fast turnaround

• Personalized service and long-term partnerships

• 100% in-house repair & coating operations

Relations

The company is intensively augmenting its scientific and technical potential partly thanks to the close cooperation with LLC Paton Turbine Technologies (Ukraine) where Sigmatech Ltd has a 51% stake.

LLC Paton Turbine Technologies (former Pratt & Whitney-Paton until 2014) was founded in 1993 as a joint venture between Pratt & Whitney (United Technologies Corporation, USA) and E. O. Paton Electric Welding Institute of National Academy of Sciences of Ukraine.